Features and Benefits

- Widest selection in the oilfield

FMC offers the most complete line of standard service and sour gas wing unions with sizes ranging from 1- to 12-inches in diameter with working pressures up to 20,000 psi. Unions are available with line pipe or tubing threads, butt-weld, or nonpressure-thread seal end connections.

- Positive sealing designs

Weco wing union seals vary according to pressure and application. All wing unions provide positive, pressure-tight sealing.

- Fast make-up and break-out

Three-lug nuts and rugged self-locking ACME threads provide fast make-up and break-out regardless of position or space restrictions. No special tools are required.

- Simple Identification

Weco standard service wing unions are color coded for quick identification.

- Interchangeable parts

All Weco parts of the same size, pressure rating, and figure number are interchangeable.

- Rigid quality control

Weco unions are produced using the finest raw materials, tooling procedures, and heat-treating techniques available. Each union is carefully inspected to assure long, dependable service in the most extreme conditions.

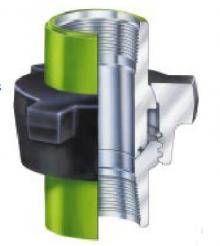

Weco® Original Wing Unions

Figure 100

1,000 psi (69 bar) cold working pressure

Recommended service: Manifold and line connections

Features: Pressure-tight make-up with hammer, economical low-pressure union

Figure 200

2,000 psi (138 bar) cold working pressure

Recommended service: General-service manifolds and lines

Features: Economical, general-purpose union, 1- to 4-inch sizes, butt-weld available

Figure 206

2,000 psi (138 bar) cold working pressure

Recommended service: Manifold and line connections, suction service, and corrosion service

Features: O-ring in male sub improves sealing and protects metal-to-metal seal against corrosion, replaceable O-ring extends union service life, 1- to 10-inch sizes

Figure 207

Blanking union, 2,000 psi (138 bar) cold working pressure

Recommended service: To seal manifold connections and protect union threads

Features: Parts are interchangeable with Figs. 200 and 206, O-ring on blanking cap ensures a leak-free seal, Raised lugs on cap allow for make-up with a hammer, Available in butt-weld, Cap can be tapped for pressure gauge if specified

Figure 211

Insulating union, 2,000 psi (138 bar) cold working pressure

Recommended service: For production systems with electrolytic corrosion problems

Features: Laminated insulating rings eliminate all metal-to-metal contact; insulating rings provide 35 million ohms resistance across the union, O-ring in male sub provides a positive primary seal, Seal ring in female sub provides a positive secondary seal, Insulating rings, O-ring, and seal ring can be replaced to extend union life

Figure 400

4,000 psi (276 bar) cold working pressure through 4-inch sizes;

2,500 psi (172 bar) cold working pressure, 5- through 12-inch sizes

Recommended service: Manifold and line connections, pump suction, and mud service

Features: 2 1/2- through 12-inch sizes have O-rings for primary seal, Butt-weld available, Available for sour gas service: 2,500 psi (172 bar) cold working pressure, 5- through 12-inch sizes; 4,000 psi (276 bar) cold working pressure, 1- through 4-inch sizes

Figure 600

6,000 psi (414 bar) cold working pressure

Recommended service: Steam service, boiler connections, manifold, and line connections for production, drilling and well servicing

Features: Bronze seat provides primary seal; will not rust in water services

Figure 602

6,000 psi (414 bar) cold working pressure

Recommended service: Manifold and line connections and mud service

Features: Compact, Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 6,000 psi (414 bar) cold working pressure

Figure 1002

10,000 psi (690 bar) cold working pressure through 4-inch sizes;

7,500 psi (517 bar) cold working pressure, 5- and 6-inch sizes

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Feature: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 7,500 psi (517 bar) cold working pressure, 5- and 6-inch sizes have O-rings for primary seals

Figure 1003

Misaligning union, 10,000 psi (690 bar) cold working pressure, 2- and 3-inch sizes;

7,500 psi (517 bar) cold working pressure, 4- and 5-inch sizes

Recommend service: For high-pressure connections where lines cannot be aligned

Features: Ball seat provides positive seal with up to 71/2° misalignment; 2-inch model up to 4°, Replacement O-ring on male sub provides primary seal, and protects metal-to-metal seal against abrasion and corrosion, Available with threaded or butt-weld ends

Figure 1502

15,000 psi (1034 bar) cold working pressure

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Features: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 10,000 psi (690 bar) cold working pressure; buttweld or nonpressure-thread seal configurations only

Figure 2002

20,000 psi (1380 bar) cold working pressure

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Features: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, 2- and 3-inch line sizes, Butt-weld configurations only

Figure 2202

15,000 psi (1034 bar) cold working pressure

Recommended service: Especially designed for sour gas service

Features: Meets National Association of Corrosion Engineers Standard MR-01-75 and American Petroleum Institute RP-14E, Heat-treated components are 100% tested for hardness, Fluoroelastomer seal rings, Butt-weld only, Stamped “sour gas” using low-stress dot stamping and painted with a green zinc-chromate primer to assure quick identification

Download FMC Weco® Wing Union Catalog for more details and specifications.